Meconet manufactures various sheet metal components for the rollers and conveyor platforms of K. Hartwall. Our co-operation has lasted for more than ten years. The secret to a long partnership is a deep understanding of the customer’s needs and an ability to meet these needs flexibly and effectively.

Roller and conveyor platform components are manufactured in all Meconet factories: springs in Pihtipudas, deep drawn parts in Äänekoski, press parts serial production in Vantaa, as well as serial production and further hand-made processing in Tallinn.

“The aim is to continuously improve product performance and reduce costs at the same time.”

The core of successful co-operation is mutual interest in the partner’s activities. We have been willing to learn the way our customer operates. And thus, we can help K. Hartwall design their products.

Development never ends

Continuous product development is essential. The aim is to continuously improve product performance and reduce costs at the same time. For some customers of K. Hartwall, we have designed fully customized rollers or conveyor platforms to suit their specific needs.

Another key area is improving material efficiency. By thinning the raw materials used, the costs can be reduced significantly. It is important to understand the purpose of each component. Testing is then used to find sufficient thickness.

“Each kilogram of steel saved is equivalent to three kilograms of reduced carbon dioxide emissions.”

Material savings are not only economically sensible, but they also reduce the impact of production on the environment: each kilogram of steel saved is equivalent to three kilograms of reduced carbon dioxide emissions.

Anticipating demand for two different needs

Meconet delivers parts for K. Hartwall in two different ways. For the parts in constant and steady demand, Meconet has arranged a Kanban stock, and these products are retrieved from the factories on a daily basis. The second part of the whole is project-specific demand peaks. In both cases, foresight is crucial. Reliable delivery and meeting deadlines require regular communication and planning.

“Meconet offers valuable expertise and practical suggestions, which makes them our valuable partner.”

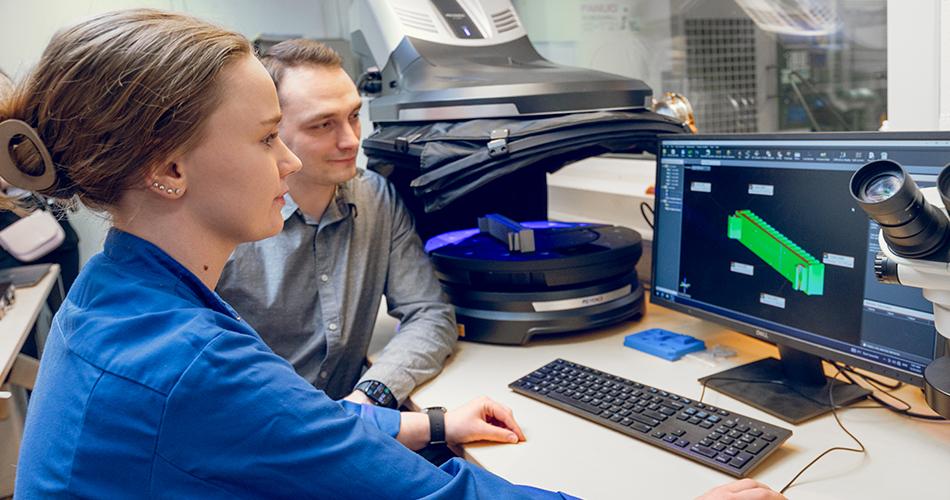

“We have managed to optimize the material thickness of components by means of rigid moulding, for example. The benefits of rapid prototyping before serial production are also undeniable. Meconet offers valuable expertise and practical suggestions, which makes them a valuable partner for us,” says Jussi Raninen, the Team Leader R&D of K. Hartwall.

Our co-operation with K. Hartwall has lasted for a long time. Watch our co-operation video (from 2019) : The foldable hinge system Foldia of K. Hartwall was designed to serve as many customers as possible. The embossing method was a viable solution for the best end result.

Interested in working with us? Contact us and let’s discuss it further!

Blog

Reduce Your Company's Carbon Footprint with Low-Carbon Steel

The Earth is warming at a dangerous pace impacting us all. Carbon dioxide emissions must be significantly and rapidly reduced. So we must act now. Meconet, along with its partner network, is now offering its customers the opportunity to impact their own CO2 emissions through the use of low-carbon steel.

Read more